Laser welding machines are widely used for high-precision metal joining in modern manufacturing industries, including automotive production, metal fabrication, machinery manufacturing, electronics, and industrial equipment processing. Compared with traditional welding methods, laser welding offers higher accuracy, faster speed, lower heat input, and cleaner weld seams, making it an ideal solution for welding stainless steel, aluminum, carbon steel, copper, and various metal alloys.

As a professional laser welding machine manufacturer in China, we focus on designing and producing industrial-grade laser welding solutions for global B2B customers. Our laser welders are engineered for stable performance, easy operation, and long-term industrial use, helping manufacturers improve production efficiency while reducing labor and rework costs.

Wide Range of Laser Welding Machines for Industrial Applications

To meet different production needs, we offer a complete range of laser welding machines, covering various power levels, structures, and working modes.

Our laser welding product line includes:

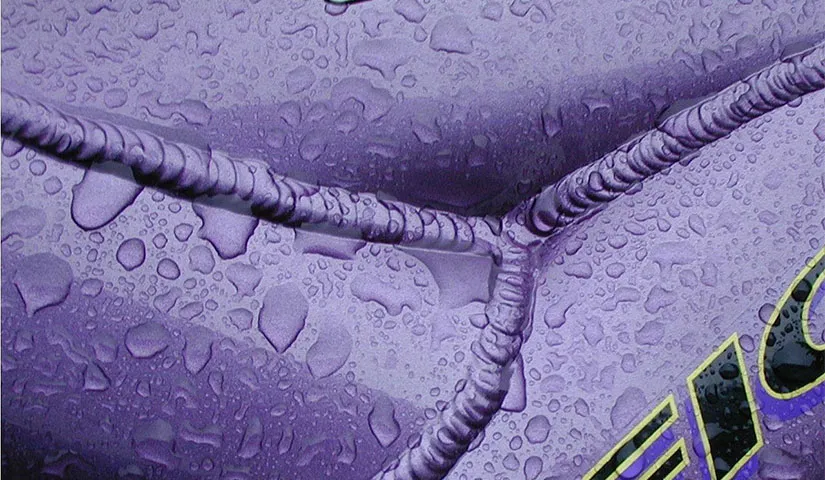

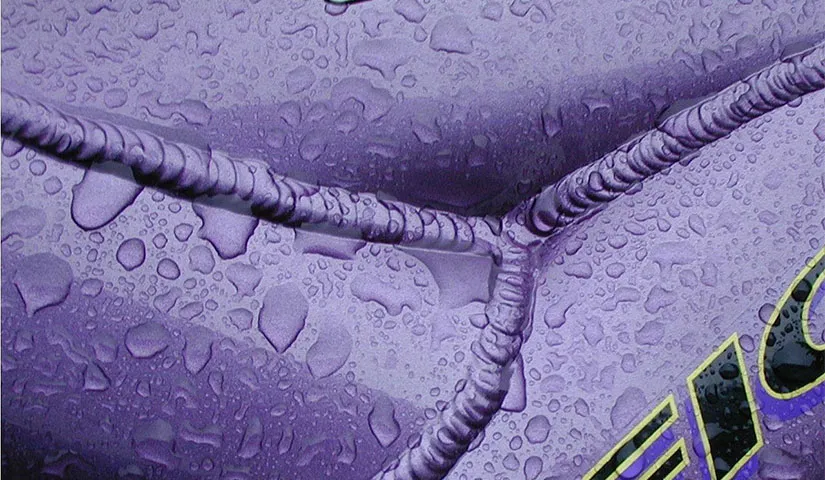

Handheld Laser Welding Machines

Ideal for flexible welding tasks, on-site operations, and small-to-medium batch production. Handheld laser welders are easy to operate and widely used in metal workshops, cabinets, doors, frames, and sheet metal fabrication.

Fiber Laser Welding Machines

Designed for high efficiency and deep penetration welding, suitable for stainless steel, aluminum, and carbon steel. Fiber laser welders provide stable beam quality and consistent welding results for industrial applications.

Industrial & CNC Laser Welding Machines

Including platform-type and automated laser welding systems, suitable for batch production, repetitive welding tasks, and integration into automated production lines.

3-in-1 Laser Welding, Cleaning & Cutting Machines

Combining welding, weld seam cleaning, and light cutting functions in one system, helping manufacturers reduce equipment investment and improve workflow efficiency.

Laser Welding Power Options & Technical Capabilities

Our laser welding machines are available in multiple power configurations to match different materials and welding thicknesses:

- Laser power range: 1000W, 1500W, 2000W, 3000W, up to 6000W

- Laser type: Fiber laser welding machine

- Weldable materials: Stainless steel, aluminum, carbon steel, galvanized sheet, copper (optional solutions)

- Cooling system: Water-cooled or air-cooled options

We support OEM and ODM customization, including laser source selection, welding head configuration, cable length, control system, cooling system, and safety options, to ensure each laser welder matches the customer’s real production requirements.

Why Choose Our Laser Welding Machines

For B-end buyers, choosing a laser welding machine is not only about price, but also about long-term reliability, consistency, and service support. As a direct manufacturer, we provide advantages that trading companies cannot offer:

- Factory-direct manufacturing with stable batch quality control

- Customized laser welding solutions for different industries and applications

- Strict quality inspection before delivery to ensure stable performance

- Export experience to multiple countries, familiar with international standards and market requirements

- Long-term technical support and spare parts supply

Our laser welders are designed for continuous industrial operation, helping customers reduce downtime and improve overall production efficiency.

Applications of Laser Welding Machines

Laser welding machines are widely applied in:

- Metal fabrication and sheet metal processing

- Cabinet, enclosure, and electrical box manufacturing

- Stainless steel doors, windows, and furniture

- Automotive parts and metal components

- Machinery manufacturing and industrial equipment

Whether for flexible manual welding or automated production lines, our laser welding solutions can be adapted to different working environments and production scales.

Get a Quote for Your Laser Welding Solution

Se está à procura de um reliable laser welding machine manufacturer or planning to upgrade your welding process with handheld or industrial laser welders, our team is ready to support you.

Contact us today to get a professional laser welding solution and quotation tailored to your production needs.