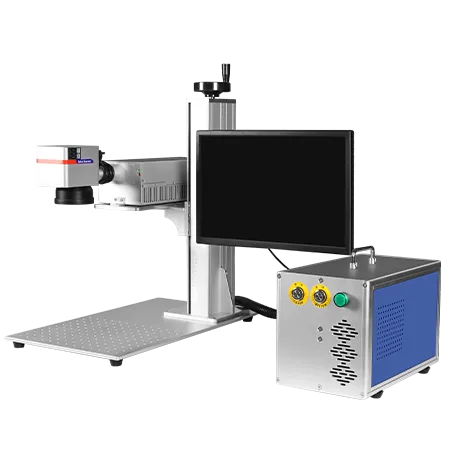

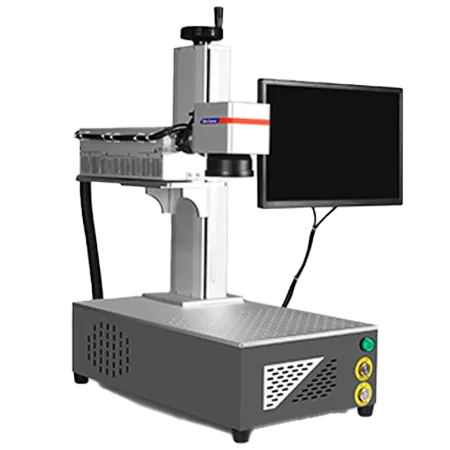

Split Fiber Laser Marking Machine

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

Fiber laser marking machine has fast marking speed and high efficiency. The photoelectric conversion efficiency is high, which greatly saves electric energy. The output beam quality is good, the service life is long, maintenance-free, no consumables, saving operating costs.

Applicable to stainless steel, carbon steel, aluminum oxide, aluminum alloy, aluminum, copper type, iron, gold, silver, cemented carbide and other metal materials surface engraving. Hard plastic, PVC material, ceramics with glaze layer, clay teapot, paper box with paint, melamine boards, mirror paint layer, graphene, chip de-lettering, cans, milk powder buckets and so on.

| Item | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Marking Speed | 1000–3000 mm/s |

| Marking Depth | 0.1–0.5 mm |

| Configuration | Bench-Top |

| Control System Brand | JCZ |

| Cooling System | Air Cooling |

| Mode of Operation | Continuous Wave |

| Key Selling Points | Flexible Manufacturing |

| Feature | Air-Cooled |

| Graphic Format Supported | AI, PLT, BMP, JPG |

| CNC or Not | Yes |

| Condition | New |

| Warranty | 2 Years |

| Working Accuracy | ±0.008 mm |

| Place of Origin | Shandong, China |

| Brand Name | JOBON |

| Control Software | JCZ |

| Marking Head Brand | SINO-GALVO |

| Weight | 40 |

| Product Name | Fiber Laser Marking Machine |

| Laser Power | 20W / 30W / 50W / 60W / 100W (Optional) |

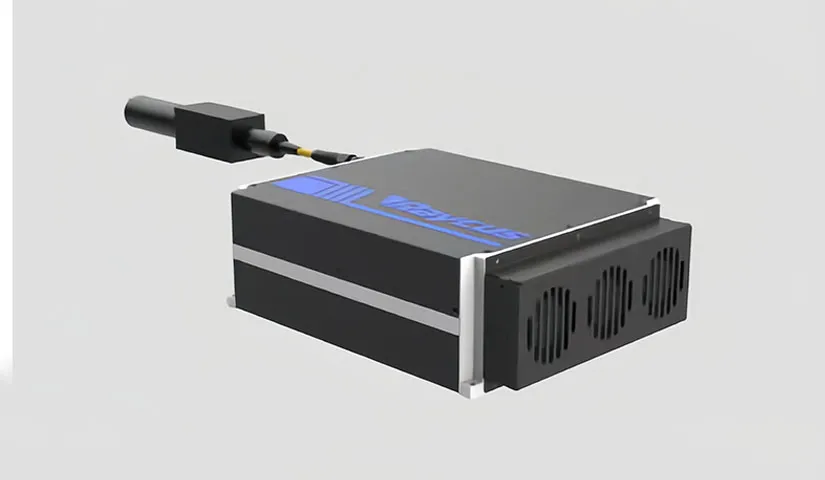

| Laser Source | Raycus / Max / JPT (Optional) |

| Applicable Material | Metal, Aluminum, Stainless Steel |

| Working Voltage | AC220V / 110V; 50Hz / 60Hz (Optional) |

| After-sales Service Provided | Video Technical Support, Online Support |

| Function | Marking Logo Metal |

| Support Format | DXF, PLT, JPG, BMP, PNG |

| Machine Type | Fiber Laser Marker |

| Cooling System | Air Cooling System |

Brand: Raycus /MAX/JPT Optional

Power:20W/30W/50W/60W/80W/100W/120W

High stability, long life span 100000+ hours.Output good laser beam.

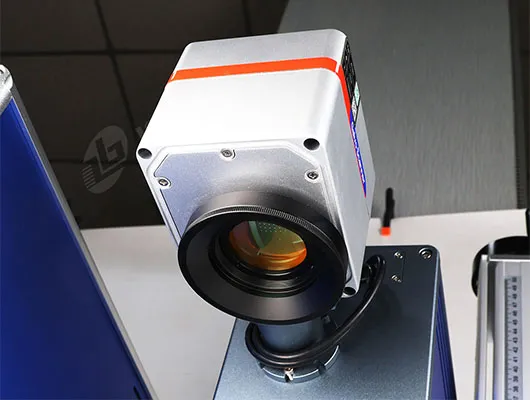

Famous brand Sino-galvo, galvanometer scanning head.

Precision marking. High quality scan, high speed galvanometer scan adopting CANLAB technology.

Famous brand lens to provide precision laser.

High transmittance lens, Multiple working area for optional.

75*75/100*100/175*175/200*200/300*300mm etc.

Genuine EZCAD control system compatible with win7/8/10. Offer multiple languages, such as Chinese,

English, Korean, Japanese, French and German.

It can be embedded in CorelDRAW, CAD, etc. It supports file formats such as AI, DXF, DST, Bmp, jpg, gif, png, tif, etc.

Aviation aluminum alloy material.

High precision density scale, accurate view of positioning size.

The machine using integrated air-cooled cooling system takes up less space and easier to use.

Foot switch*1 set

Positioning Bar*1set

U disk*1PC

Protective glasses*1set

Aluminum card for testing*1box;

Tools*1set Changeover plug*1PC

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld after welding, coating, removal of rust on metal, rapid removal of paint, etc.

Jobon is a professional laser equipment manufacturer offering full-spectrum solutions in welding, cleaning, marking, and cutting. With global voltage compatibility (110V/220V), in-house R&D and production, and CE/ISO certifications, our machines are designed for both performance and reliability across industries. We support OEM/ODM customization, fast delivery from stock or tailored production lines, and multilingual after-sales service for customers in over 60 countries. Whether you’re sourcing for industry, integration, or distribution, Jobon ensures plug-and-play deployment, stable quality, and long-term value for your business.

Flying UV laser marking machine is a high-speed inline UV marking system designed for automated, contactless, and precision marking on production lines. Utilizing ultraviolet lasers with short wavelengths and high energy density, this machine delivers ultra-fine, high-resolution marking results without damaging the substrate—making it ideal for sensitive and heat-sensitive materials.

UV laser marking machines utilize ultraviolet lasers with short wavelengths and high energy concentration, enabling high-precision and high-quality marking results. They are particularly suitable for applications involving heat-sensitive materials or requiring fine processing.

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

Our desktop fiber laser marking machine offers high-speed, high-precision marking with zero consumables and no maintenance. It features stable beam quality, long service life, and wide compatibility with metals, plastics, and coated materials—ideal for industrial engraving needs

Our desktop fiber laser marking machine offers high-speed, high-precision marking with zero consumables and no maintenance. It features stable beam quality, long service life, and wide compatibility with metals, plastics, and coated materials—ideal for industrial engraving needs

It is widely used in food and beverage, electronic components, pharmaceutical packaging and other high-volume production scenarios, significantly improve the production line efficiency and automation level.

The Jobon Portable Handheld Fiber Laser Marking Machine is expertly designed for precision marking in versatile and hard‑to‑reach environments. With an ultra‑compact, lightweight body (approx. 8.3 kg) and ergonomic handheld structure, this machine delivers portable, on‑site marking without compromise Equipped with a MAX fiber laser source featuring a long service life and reliable continuous‑wave operation, the system supports high‑speed marking up to 12,000 mm/s with excellent beam quality and stable performance. The built‑in 7‑inch touch controller and real‑time positioning aid simplify setup and allow quick adjustment of parameters directly from the interface.

Our desktop UV laser marking machine is engineered for ultra-high precision and delicate material processing. Utilizing short-wavelength ultraviolet lasers, this compact and efficient system delivers highly focused energy that produces sharp, high-contrast, and non-contact markings without thermal damage. It is the ideal solution for industries requiring micro-engraving, fine etching, or coding on heat-sensitive and complex surfaces. This UV laser engraver stands out with its compact desktop design, low power consumption, and maintenance-free air cooling system, making it perfect for cleanrooms, labs, and small production environments.

West side of the first floor, North Workshop, No.13 huaxianchang Road, Lixia District, Jinan City, Shandong Province, China

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.