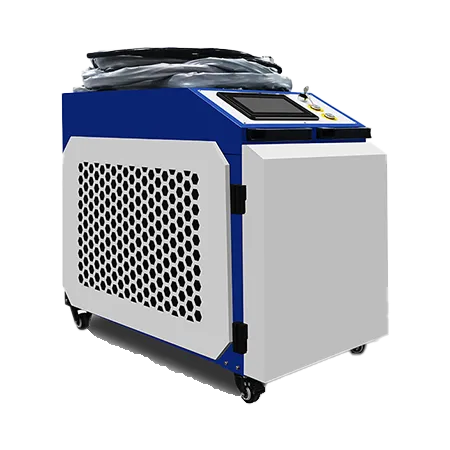

Máquina de limpeza a laser CW - Modelo A

A máquina de limpeza a laser adopta uma limpeza sem contacto, que poupa energia e é amiga do ambiente, e não tem poluição secundária.

An oxide layer is a thin film formed on the surface of a metal when it reacts with oxygen in the environment. This reaction can occur naturally or through controlled treatment processes. The oxide layer serves as a chemical boundary between the metal and the surrounding atmosphere.

The oxide layer typically has a dense or partially porous structure, depending on the metal and reaction conditions. A dense oxide layer tightly adheres to the metal surface and prevents further penetration of oxygen and moisture, thereby slowing or stopping corrosion. In contrast, porous oxide layers allow continuous diffusion of oxygen and water, enabling corrosion to progress deeper into the metal.

Our Laser Cleaning Machines offer an efficient, non-contact, and environmentally friendly solution for removing rust, oxide layers, paint, coatings, grease, and surface residues from metals and industrial equipment. Designed for precision and flexibility, these machines are ideal for applications across automotive, aerospace, electronics, petrochemical, and manufacturing industries.

Featuring fiber laser sources from 100W to 2000W, our models deliver high-speed cleaning, stable beam quality, and low maintenance. From handheld portable units to integrated robotic cleaning systems, we support custom designs tailored to your specific cleaning tasks—whether it’s fine weld cleaning, large-area paint removal, or surface preparation before coating

Pulsed laser cleaning uses high-energy laser pulses to irradiate the metal surface, instantly vaporizing or ablating the oxide layer without damaging the underlying substrate. Unlike traditional mechanical or chemical cleaning methods, laser cleaning is non-contact, requires no consumables, and produces no secondary pollution.

The system delivers precise and selective cleaning even in small areas or complex surfaces. Thanks to its low thermal impact, it preserves the physical properties of the base material, making it ideal for pre-welding, plating, or bonding processes where oxide layers must be thoroughly removed to ensure strong adhesion and optimal conductivity.

Rust removal is critical in metal maintenance, repair, and surface treatment. While traditional rust removal methods remain widely used, laser cleaning technology is quickly emerging as a safer, more efficient, and eco-friendly alternative. Below is a comparison of laser rust removal and conventional methods, categorized by their working principles.

| Caraterística | Laser Rust Removal | Traditional Methods |

|---|---|---|

| Contact Type | Non-contact, no tool wear | Physical or chemical contact |

| Base Material Damage | Minimal, especially with pulsed lasers | High risk of surface damage or pitting |

| Precisão | High (suitable for delicate parts) | Low (broad impact area) |

| Impacto ambiental | No chemicals or waste | Generates hazardous waste or dust |

| Operation Cost | Higher initial investment, low maintenance | Low initial cost, high recurring costs |

| Automation Integration | Easy to integrate into CNC/robot systems | Difficult to automate |

| Noise & Safety | Low noise, safer working environment | Loud, requires protective measures |

A máquina de limpeza a laser adopta uma limpeza sem contacto, que poupa energia e é amiga do ambiente, e não tem poluição secundária.

É adequado para navios, caldeiras, superfícies de aço, tratamento de superfícies de produtos antes da soldadura, tratamento da camada de óxido dentro e à volta da soldadura após a soldadura, revestimento, remoção de ferrugem no metal, remoção rápida de tinta, etc.

É adequado para navios, caldeiras, superfícies de aço, tratamento de superfícies de produtos antes da soldadura, tratamento da camada de óxido dentro e à volta do cordão de soldadura após a soldadura, revestimento, remoção de ferrugem no metal, remoção rápida de tinta, etc.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

É adequado para navios, caldeiras, superfícies de aço, tratamento de superfícies de produtos antes da soldadura, tratamento da camada de óxido dentro e à volta do cordão de soldadura após a soldadura, revestimento, remoção de ferrugem no metal, remoção rápida de tinta, etc.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

Ajudamo-lo a escolher a máquina adequada e partilhamos a solução; pode partilhar connosco as seguintes informações

1. que material vai soldar

2. A espessura do material de soldadura

3. Trata-se de soldadura de juntas ou de soldadura por sobreposição

4. Qual é a utilização exacta da máquina, para soldadura ou reparação de produtos ou outra aplicação

Enviaremos o vídeo de funcionamento e o manual da máquina. O nosso engenheiro fará a formação online, se necessário. Podemos enviar o nosso engenheiro ao seu local para formação ou pode enviar o operador à nossa fábrica para formação.

Fornecemos dois anos de garantia da máquina. Durante a garantia de dois anos, em caso de qualquer problema com a máquina, forneceremos as peças gratuitamente (exceto para danos artificiais). Após a garantia, continuamos a fornecer um serviço vitalício. Por isso, se tiver dúvidas, diga-nos, nós damos-lhe soluções.

Aceitamos condições de pagamento, incluindo: T/T, VISA, Western Union, pagamento bancário online.

O transporte marítimo é a forma normal. Se houver requisitos especiais, as duas partes precisam de confirmar o final.

Responder-lhe-emos no prazo de 24 horas. Se for um caso urgente, adicione WhatsApp/WeChat: +86 18053185411,.

*Respeitamos a sua confidencialidade e todas as informações são protegidas.

Apenas utilizaremos as suas informações para responder ao seu pedido e nunca enviaremos mensagens de correio eletrónico ou mensagens promocionais não solicitadas.