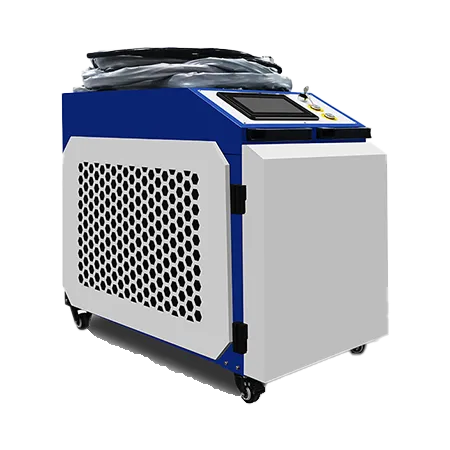

Máquina de limpeza a laser CW - Modelo A

A máquina de limpeza a laser adopta uma limpeza sem contacto, que poupa energia e é amiga do ambiente, e não tem poluição secundária.

Oil stains and carbon buildup on engine components mainly result from incomplete fuel combustion and oil leakage. During operation, unburnt fuel and leaked engine oil are exposed to high temperatures, forming sticky residues and soot. These deposits commonly appear on pistons, valves, injectors, and cylinder heads, especially in engines using poor fuel, experiencing short trips, or suffering from worn seals.

Over time, they reduce performance, increase wear, and make cleaning or reassembly more difficult—requiring precise and non-damaging methods like laser cleaning.

Oil stains and carbon buildup on engine components reduce efficiency, increase wear, and cause overheating. These residues disrupt combustion, block cooling and lubrication channels, and lead to emission failures. For surface treatment or remanufacturing, contaminants prevent proper bonding and compromise repair quality.

Laser cleaning offers a safe, non-contact solution to remove stubborn deposits without damaging the base metal—ideal for automotive manufacturing and maintenance.

In the automotive industry, engine components are often subjected to stubborn oil stains, grease, and carbon buildup—especially during manufacturing, repair, or remanufacturing. Laser cleaning offers a precise, non-contact, and eco-friendly solution for restoring these parts without damaging sensitive surfaces or requiring disassembly.

Unlike traditional cleaning methods that rely on chemicals or abrasives, laser cleaning machines use high-energy beams to break molecular bonds of oil and carbon layers. The contaminants are instantly vaporized or ejected, leaving the metal substrate intact and ready for further processing, such as coating, welding, or assembly.

Whether you’re cleaning parts before engine reassembly, quality inspection, or remanufacturing, laser cleaning delivers a cost-effective, high-efficiency solution tailored to modern automotive production and repair standards.

| Aspect | Laser Cleaning | Traditional Methods |

|---|---|---|

| Cleaning Principle | High-energy laser beam breaks down oil & carbon at surface | Chemical solvents or mechanical scrubbing |

| Efficiency | Fast, precise, and localized cleaning | Time-consuming and labor-intensive |

| Surface Safety | Non-contact, no abrasion or surface damage | Risk of scratching, pitting, or material fatigue |

| Residue Handling | Minimal residue; easy collection via fume extraction | Requires chemical waste disposal |

| Impacto ambiental | Eco-friendly, no harmful chemicals | Uses toxic chemicals; environmental hazard |

| Cost Over Time | Higher initial cost, lower operating cost | Low initial cost, higher long-term cost (consumables, labor) |

| Maintenance Needs | Low, only optics and filters | Frequent replacement of brushes, chemicals, tools |

| Worker Safety | No chemical exposure, reduced manual contact | Chemical fumes, manual handling risks |

| Precisão | High – adjustable parameters for delicate components | Low – difficult to control uniformly |

| Automation Potential | Easily integrated into robotic or automated cleaning lines | Mostly manual, difficult to automate |

A máquina de limpeza a laser adopta uma limpeza sem contacto, que poupa energia e é amiga do ambiente, e não tem poluição secundária.

É adequado para navios, caldeiras, superfícies de aço, tratamento de superfícies de produtos antes da soldadura, tratamento da camada de óxido dentro e à volta da soldadura após a soldadura, revestimento, remoção de ferrugem no metal, remoção rápida de tinta, etc.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

É adequado para navios, caldeiras, superfícies de aço, tratamento de superfícies de produtos antes da soldadura, tratamento da camada de óxido dentro e à volta do cordão de soldadura após a soldadura, revestimento, remoção de ferrugem no metal, remoção rápida de tinta, etc.

É adequado para navios, caldeiras, superfícies de aço, tratamento de superfícies de produtos antes da soldadura, tratamento da camada de óxido dentro e à volta do cordão de soldadura após a soldadura, revestimento, remoção de ferrugem no metal, remoção rápida de tinta, etc.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

Ajudamo-lo a escolher a máquina adequada e partilhamos a solução; pode partilhar connosco as seguintes informações

1. que material vai soldar

2. A espessura do material de soldadura

3. Trata-se de soldadura de juntas ou de soldadura por sobreposição

4. Qual é a utilização exacta da máquina, para soldadura ou reparação de produtos ou outra aplicação

Enviaremos o vídeo de funcionamento e o manual da máquina. O nosso engenheiro fará a formação online, se necessário. Podemos enviar o nosso engenheiro ao seu local para formação ou pode enviar o operador à nossa fábrica para formação.

Fornecemos dois anos de garantia da máquina. Durante a garantia de dois anos, em caso de qualquer problema com a máquina, forneceremos as peças gratuitamente (exceto para danos artificiais). Após a garantia, continuamos a fornecer um serviço vitalício. Por isso, se tiver dúvidas, diga-nos, nós damos-lhe soluções.

Aceitamos condições de pagamento, incluindo: T/T, VISA, Western Union, pagamento bancário online.

O transporte marítimo é a forma normal. Se houver requisitos especiais, as duas partes precisam de confirmar o final.

Responder-lhe-emos no prazo de 24 horas. Se for um caso urgente, adicione WhatsApp/WeChat: +86 18053185411,.

*Respeitamos a sua confidencialidade e todas as informações são protegidas.

Apenas utilizaremos as suas informações para responder ao seu pedido e nunca enviaremos mensagens de correio eletrónico ou mensagens promocionais não solicitadas.