| Heat Input |

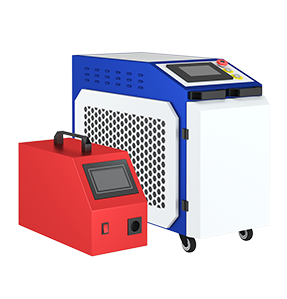

Low heat input, minimal thermal distortion |

High heat input, prone to warping |

| Welding Speed |

High-speed welding with consistent quality |

Slower, especially for precision work |

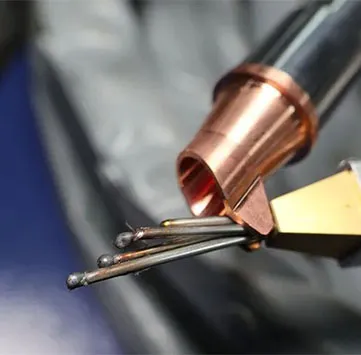

| Precision |

Extremely precise, suitable for micro welds and automation |

Moderate, heavily reliant on operator skill |

| Automation Compatibility |

Easily integrated with robotic systems and CNC |

Limited automation, mostly manual or semi-automatic |

| Material Compatibility |

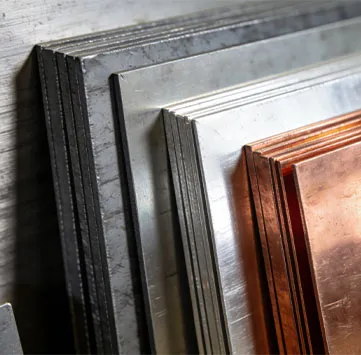

Works on metals like stainless steel, carbon steel, aluminum, copper, etc. |

Limited for certain thin, reflective, or dissimilar materials |

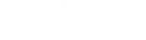

| Post-Weld Finish |

Clean, smooth welds with minimal spatter or rework |

Requires grinding, cleaning, or finishing |

| Penetration Control |

Precise control via laser power and pulse parameters |

Varies based on electrode, arc control |

| Heat-Affected Zone (HAZ) |

Narrow HAZ, preserves base material strength |

Wide HAZ, risk of structural weakening |

| Consumables |

No filler wire, gas optional (e.g., for fiber laser) |

Requires filler rods, shielding gases, flux, etc. |

| Maintenance & Downtime |

Low maintenance, fewer wear parts |

Higher wear (torch, nozzles, electrodes) |

| Energy Efficiency |

High efficiency, focused energy delivery |

Less efficient, energy loss via arc radiation |

| Operator Skill Requirement |

Easy to automate, reduces labor dependency |

Requires trained welders, skill-sensitive process |

| Environmental Impact |

Clean process, minimal fumes, no slag |

Produces smoke, slag, toxic gases depending on materials used |

| Initial Investment |

Higher upfront cost (equipment & system integration) |

Lower equipment cost |

| Long-Term Cost |

Lower operating cost, reduced labor & consumables |

High recurring costs for labor, consumables & rework |