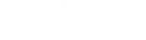

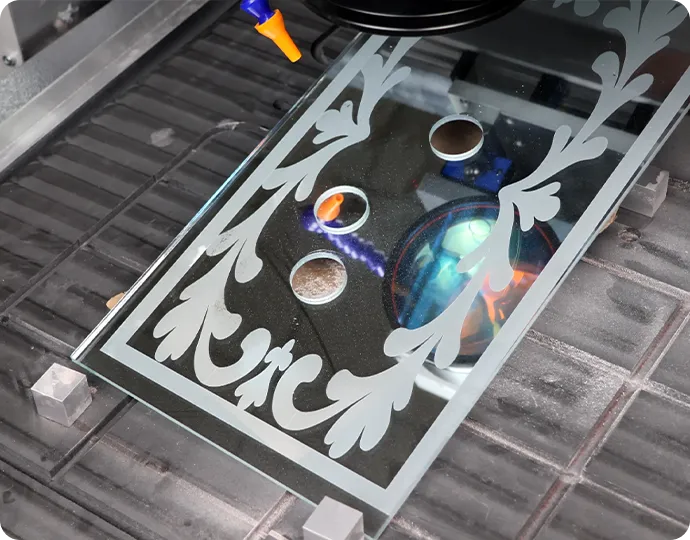

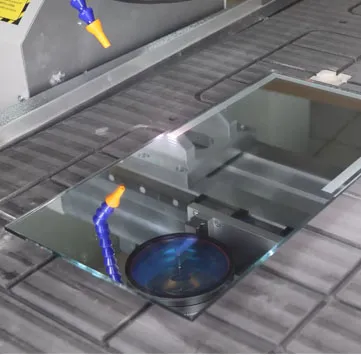

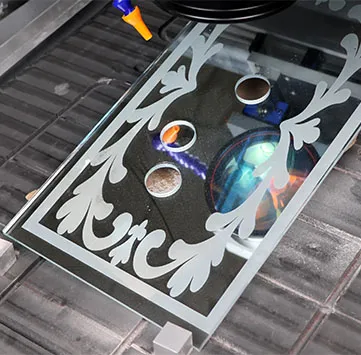

Laser sandblasting machine

Smart mirror laser sandblasting is a new type of environmentally friendly and energy-saving deep processing technology (sandblasting, paint stripping, punching), it can remove the protective paint froml smart mirrors and lacquered glass in a single pass and achieves a frosted effect. Fast speed does not hurt the mirror and glass surface, the mirror is transparent and no residue after processing, no matter silver and copper coating, it can realize the fast laser sanding.