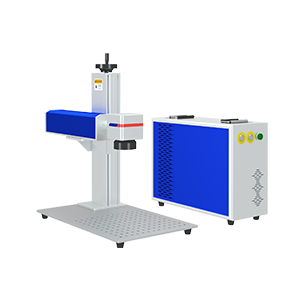

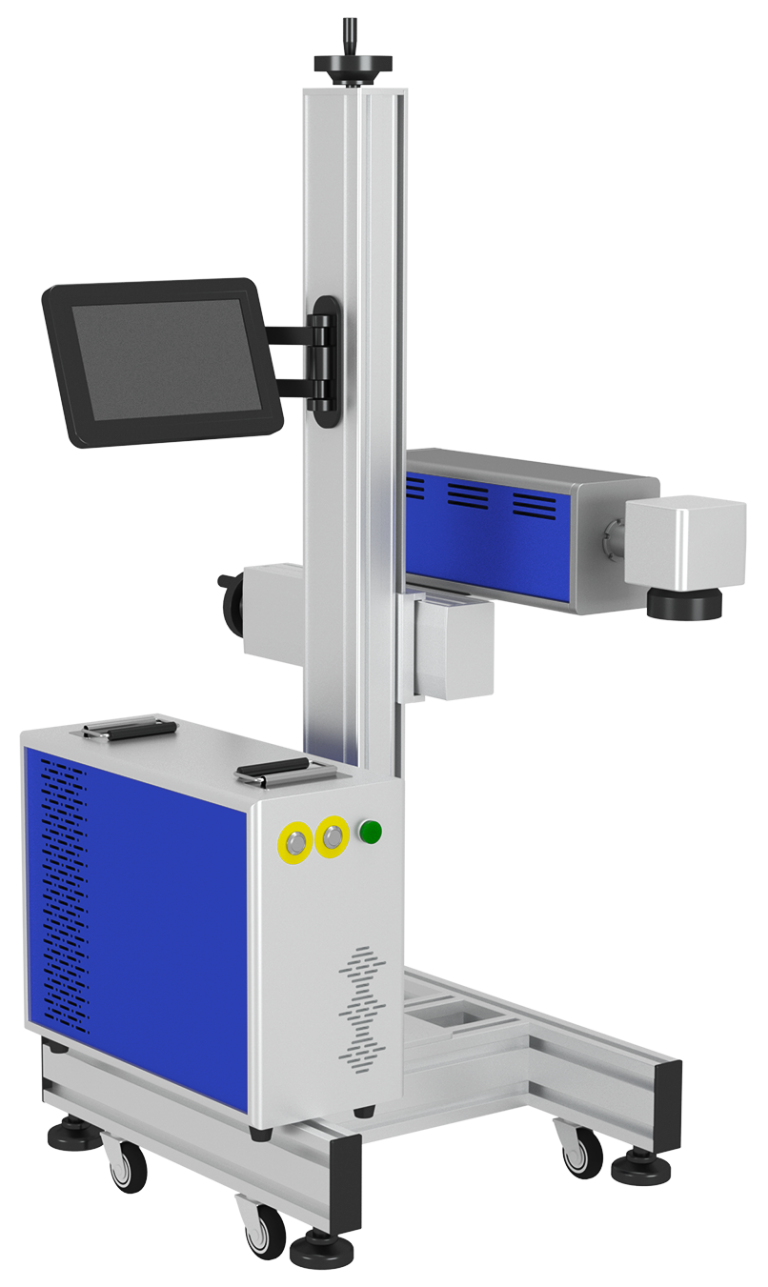

Split Fiber Laser Marking Machine

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

Laser marking machines use a high-speed, high-precision laser beam to permanently mark logos, serial numbers, QR codes, and graphics on various materials. They ensure non-contact, wear-resistant, and high-contrast results—ideal for automated, high-efficiency production.

A focused laser beam alters the surface material through thermal or chemical reaction. Depending on the laser type (fiber, CO₂, UV), marking is achieved via etching, engraving, annealing, or foaming—without damaging the base material.

Widely used in electronics, tools, auto parts, medical devices, packaging, and daily goods. Suitable for metals (stainless steel, aluminum), plastics, ceramics, and more—meeting traceability and branding needs with permanent, precise markings.

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

UV laser marking machines utilize ultraviolet lasers with short wavelengths and high energy concentration, enabling high-precision and high-quality marking results. They are particularly suitable for applications involving heat-sensitive materials or requiring fine processing.

Using a sealed CO₂ laser tube, the system provides excellent beam quality and high electro-optical conversion efficiency. Whether used for wood, acrylic, leather, paper, or glass, the machine ensures smooth engraving, fast marking speeds, and clear results with minimal power consumption. Its integrated desktop design makes it compact and space-saving, ideal for small workshops or retail production environments. With optional rotary attachments and air or water cooling systems, this CO₂ laser marker combines flexibility with reliability—suitable for labeling, barcodes, logos, and serial numbers in batch or custom production scenarios.

Our desktop UV laser marking machine is engineered for ultra-high precision and delicate material processing. Utilizing short-wavelength ultraviolet lasers, this compact and efficient system delivers highly focused energy that produces sharp, high-contrast, and non-contact markings without thermal damage. It is the ideal solution for industries requiring micro-engraving, fine etching, or coding on heat-sensitive and complex surfaces. This UV laser engraver stands out with its compact desktop design, low power consumption, and maintenance-free air cooling system, making it perfect for cleanrooms, labs, and small production environments.

The split CO2 laser marking machine adopts a compact split design, making it ideal for limited workspace and flexible deployment. Utilizing a 10.6μm wavelength infrared laser, it performs non-contact marking with high precision and efficiency. With available laser power options of 40W, 60W, and 100W, it is suitable for various marking tasks across different industries. The machine is equipped with an air-cooled system, ±0.003mm precision, and optional marking areas from 75×75 mm to 300×300 mm. It offers stable performance and low maintenance, making it a reliable solution for non-metallic material engraving and cutting.

Flying laser marking machine (in-line laser marking machine) is a dynamic laser marking equipment designed for high-speed production in assembly line, which can realize accurate and contactless marking during continuous movement of products. Through the synchronized tracking technology, combined with the high response galvanometer system, it can complete the real-time marking of text, pattern, 2D code and other information without stopping the line. With the core of "high efficiency, intelligence, and stability", Flying Laser Marking Machine provides a fully automated marking solution for the mass production in the era of Industry 4.0.

Ultra-fine laser beam ensures high-resolution, permanent marking on metals, plastics, and more — no fading or wear over time.

Supports high-speed, batch processing with clear and stable results. Ideal for automated industrial production lines.

Works on stainless steel, aluminum, ABS, ceramics, glass, etc. Perfect for industries like electronics, medical, automotive, and packaging.

Touchscreen UI, supports auto feeding, barcode/QR code reading, and ERP/MES system integration for Industry 4.0.

| Feature | Laser Marking | Traditional Marking |

| Marking Method | Non-contact laser beam focused on the surface | Contact-based: dot peen, inkjet, chemical etching |

| Precision | Ultra-high (±0.01mm), ideal for fine detail | Lower precision, prone to blurring |

| Material Compatibility | Metal, plastic, glass, leather, ceramic, etc. | Mainly metal; limited on plastics or glass |

| Speed | High-speed scanning with fast turnaround | Slower, depends on tool type |

| Marking Durability | Permanent, heat & corrosion resistant | May fade, wear off, or peel |

| Environmental Impact | No consumables, no emissions | Involves ink, chemicals, or noise |

| Maintenance Cost | Almost zero; long lifespan up to 100,000 hours | Frequent consumables or part replacements |

| Operator Safety | Enclosed lasers with safety protocols | Risk of noise, splashing, fumes, or contact injury |

| Automation Ready | Easy to integrate with robotic arms & conveyors | Hard to automate, usually stand-alone tools |

| Design Flexibility | Real-time software changes (text, QR, logo) | Requires physical setup changes or new ink |

| Typical Industries | Automotive, electronics, packaging, tools, medical | Traditional metalworking, low-cost marking |

| Machine Types | Fiber, UV, CO₂, Handheld, Flying Laser | Dot peen machines, chemical etching, inkjet |

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.