Why Use 3D Laser Pipe Cutting for Furniture Components?

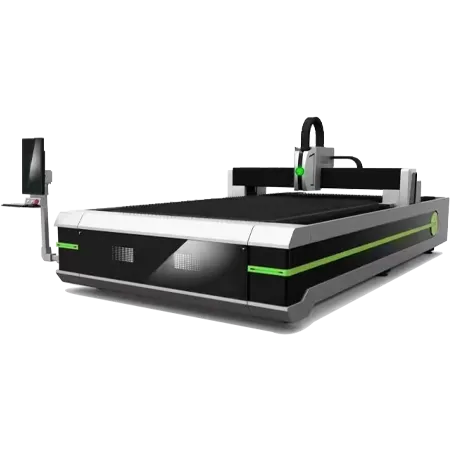

No Mold, Fast Production

Laser cutting requires no tooling, saving time in new product development and shortening design-to-production cycles.

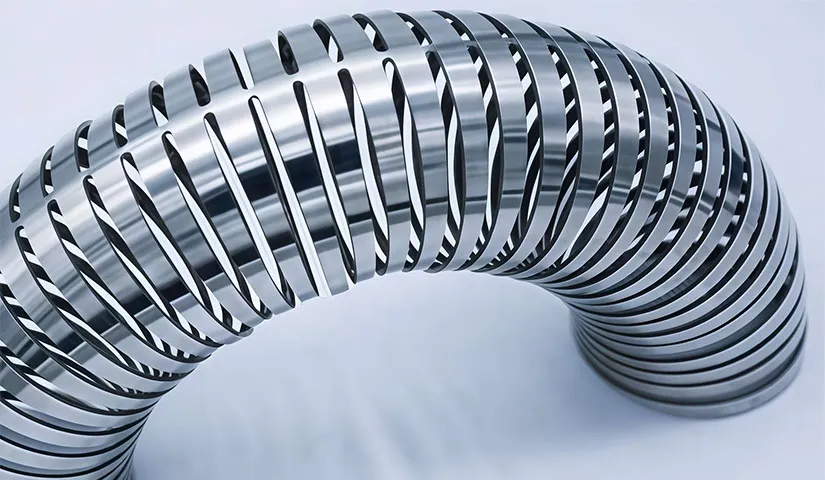

Multi-Shape Pipe Compatibility

Supports round, square, rectangular, oval, and irregular pipe profiles commonly used in beds, chairs, desks, racks, and more.

Perfect Fit & Finish

Offers small slit width (<0.2mm), low thermal deformation, and smooth cut edges—perfect for exposed structural parts.

Automation-Ready

Equipped with automatic loading/unloading systems and servo control for seamless integration into smart furniture factories.

Material Versatility

Suitable for carbon steel, stainless steel, aluminum alloy, and other metals used in modern household furniture frames.