Split Fiber Laser Marking Machine

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

Nitrogen (N₂) is an odorless, colorless, and inert gas that makes up 78% of Earth’s atmosphere. It does not support combustion or oxidation, making it widely used in industries requiring clean, dry, and oxygen-free environments.

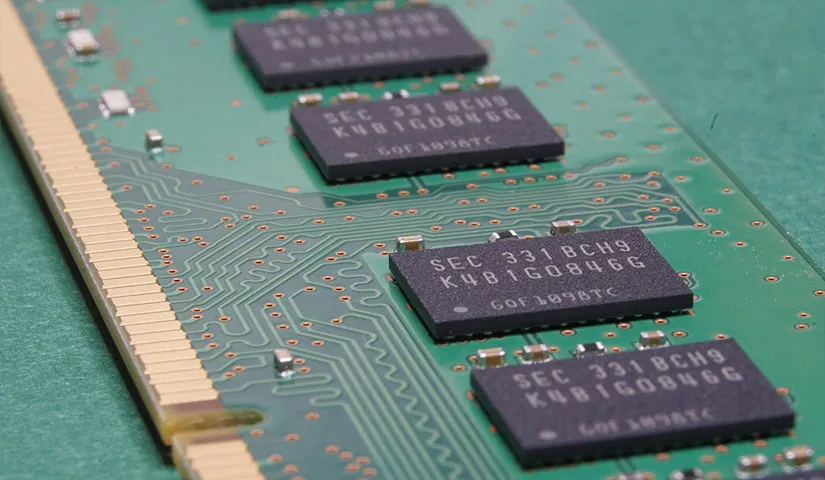

In the electronics industry, nitrogen plays a vital role in protecting sensitive components during production. It is often used in soldering, chip packaging, PCB manufacturing, and storage, helping prevent oxidation and contamination. The use of a nitrogen generator ensures a stable and cost-efficient on-site supply of high-purity nitrogen, which is critical for maintaining product quality and extending equipment lifespan.

Nitrogen generators enable real-time production of high-purity nitrogen gas, offering many advantages in electronics manufacturing:

Prevents oxidation: During reflow soldering or wave soldering, nitrogen creates an inert environment that reduces solder defects and improves joint reliability.

Improves PCB quality: Nitrogen keeps circuit boards free from oxidation, reducing bridge formation and residue during soldering.

Protects semiconductor chips: In chip packaging processes, nitrogen prevents moisture and oxygen intrusion, minimizing defects.

Reduces production costs: On-site nitrogen generation is more economical and efficient than traditional bottled gas, especially for high-volume operations.

Enhances storage safety: Nitrogen blanketing helps preserve sensitive electronic materials by creating a dry, oxygen-free environment.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.