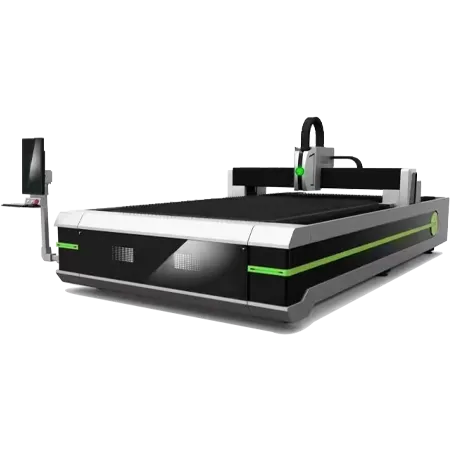

Large Format Laser Cutting Machine

Cut any design graphics on the plate;High speed, high precision, one-time forming, no subsequent processing;One machine has multiple functions, which can not only meet the cutting requirements of customers for flat plates, but also meet the requirements of round pipe and special-shaped pipes.