CW laser cleaning machine - Model A

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

Paints are liquid or semi-liquid coating materials applied to surfaces to form a thin protective and decorative film after drying. They are typically made of pigments, binders, solvents, and additives.

Paints serve multiple key functions. Their primary role is to protect surfaces from moisture, oxygen, chemicals, and environmental wear, helping prevent corrosion, fading, and surface degradation. They also provide aesthetic value by adding color, texture, and visual appeal. In many applications, paints also offer functional properties, such as insulation, fire resistance, antibacterial performance, or UV protection.

Different types of paints are used for different materials and environments. Metal surfaces often require anti-corrosion coatings, while wood uses sealants or varnishes for durability. Industrial paints may include epoxies, polyurethanes, or powder coatings for enhanced strength and long-term resistance.

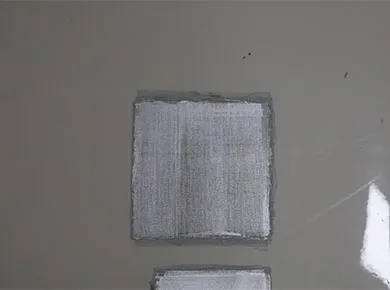

Old coatings degrade due to weathering, UV exposure, and oxidation, causing peeling, cracking, and corrosion beneath the surface. If not properly removed, these residues prevent new coatings from adhering effectively and reduce long-term protection. A clean, residue-free surface is essential before applying new paint or treatments.

Our Laser Cleaning Machines offer an efficient, non-contact, and environmentally friendly solution for removing rust, oxide layers, paint, coatings, grease, and surface residues from metals and industrial equipment. Designed for precision and flexibility, these machines are ideal for applications across automotive, aerospace, electronics, petrochemical, and manufacturing industries.

Featuring fiber laser sources from 100W to 2000W, our models deliver high-speed cleaning, stable beam quality, and low maintenance. From handheld portable units to integrated robotic cleaning systems, we support custom designs tailored to your specific cleaning tasks—whether it’s fine weld cleaning, large-area paint removal, or surface preparation before coating

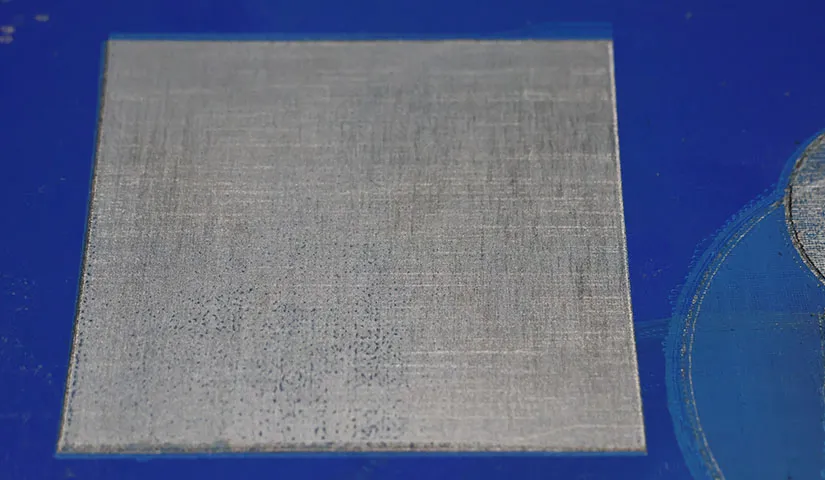

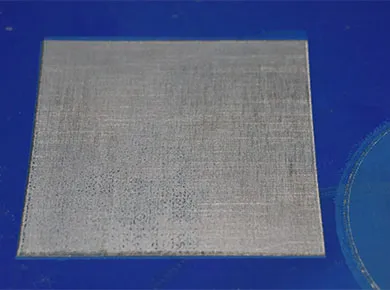

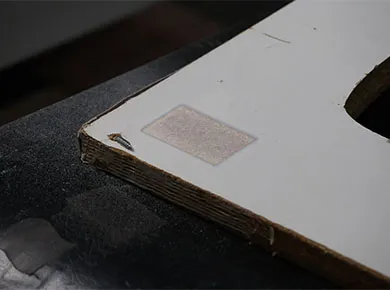

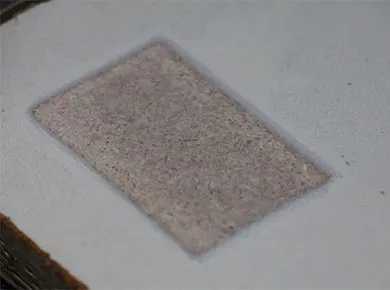

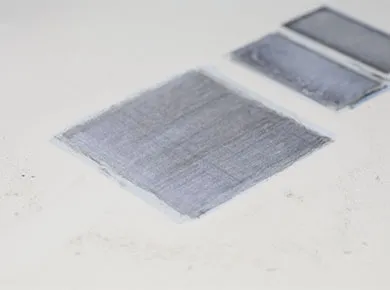

In the automotive maintenance and equipment refurbishing industries, laser cleaning is widely used for removing paint coatings from metal surfaces without damaging the underlying substrate. The process uses a high-intensity pulsed laser beam that is selectively absorbed by the paint layer, causing instant vaporization or ablation, while reflecting off the base metal.

Compared with traditional methods like sanding, chemical stripping, or abrasive blasting, laser paint removal is non-contact, precise, and environmentally friendly—eliminating the need for solvents and reducing operator fatigue.

Paint removal is essential in industries such as automotive maintenance, aerospace, metal restoration, and manufacturing. While traditional paint removal techniques like chemical stripping, sanding, and abrasive blasting are still in use, laser paint removal is rapidly emerging as a safer, cleaner, and more precise alternative. Below is a comparison of laser paint removal and conventional methods, categorized by their working principles and benefits.

| Feature | Laser Cleaning Machine | Traditional Methods |

|---|---|---|

| Contact Type | Non-contact, no tool wear | Physical or chemical contact |

| Base Material Damage | Minimal, especially with pulsed lasers | High risk of surface damage or pitting |

| Precision | High (suitable for delicate parts) | Low (broad impact area) |

| Environmental Impact | No chemicals or waste | Generates hazardous waste or dust |

| Operation Cost | Higher initial investment, low maintenance | Low initial cost, high recurring costs |

| Automation Integration | Easy to integrate into CNC/robot systems | Difficult to automate |

| Noise & Safety | Low noise, safer working environment | Loud, requires protective measures |

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

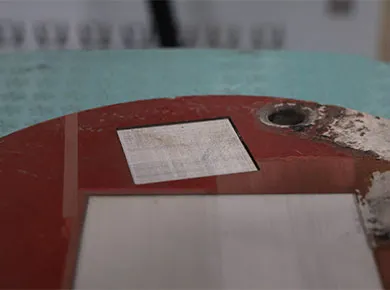

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld after welding, coating, removal of rust on metal, rapid removal of paint, etc.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.