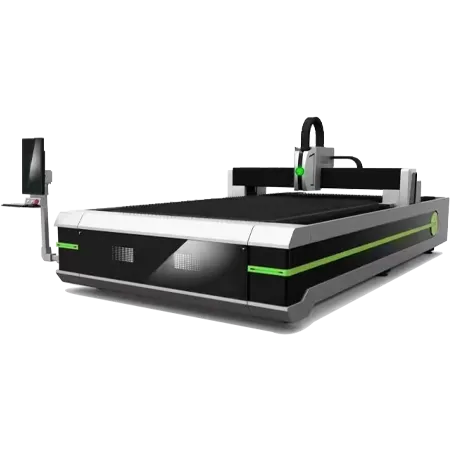

PRECISION LASER SYSTEMS FOR SIGNAGE PRODUCTION

Precision laser cutters are designed to meet the high standards of advertising and signage industries. They support both high-speed production and intricate customization, delivering smooth cuts and perfect alignment.

Versatile Material Compatibility: Supports acrylic, stainless steel, galvanized sheet, wood, MDF, and PVC.

High Accuracy: Achieves complex shapes, curves, and fonts with micron-level precision.

Automated Workflow: Easily integrates with CAD/vector files, streamlining design-to-output process.

Non-Contact Cutting: No mechanical pressure, no edge burning or distortion.

Efficient & Eco-Friendly: Minimal maintenance, no need for consumables like blades or molds.