El Tipi Hava Soğutmalı Lazer Kaynak Makinesi: Daha Hızlı, Daha Temiz Kaynaklar için Taşınabilir Lazer Kaynak Makinesi Seçmeye Yönelik Pratik Kılavuz

Production deadlines keep getting tighter, yet traditional welding still eats time with sp…

Üreticiler yavaş ve tutarsız işaretleme ile mücadele eder; seri numaraları kaybolur, logolar bulanıklaşır ve geleneksel gravür aletleri bozulur. Bu sorunlar zaman ve para kaybına yol açıyor. Modern bir çözüme ihtiyaç vardır. Bölünmüş fiber lazer markalama makinesi tutarsızlığı ortadan kaldırır ve metaller ve plastikler üzerinde hızlı, net ve kalıcı işaretler verir.

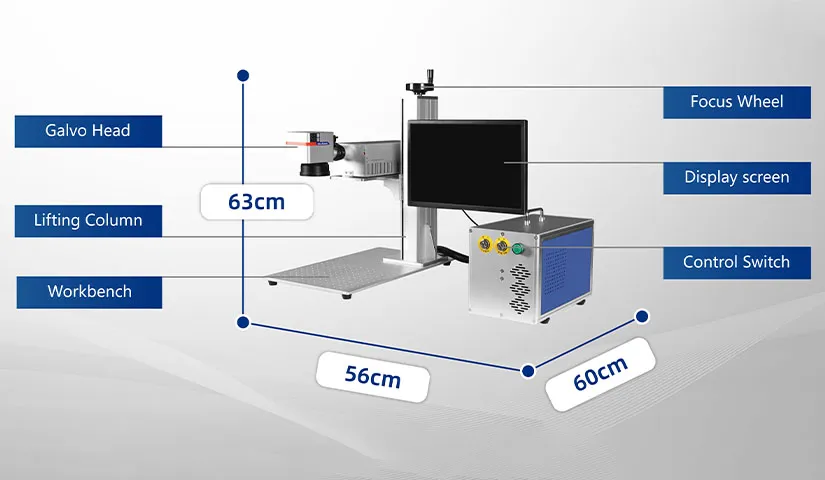

A split fiber laser marking machine is a high-precision fiber laser marking system designed to engrave and mark metals and selected plastics quickly and permanently. Using a separated control unit and head, it offers flexible setup, clear output, strong beam quality, and fast marking speeds. It is widely used for industrial part identification, logos, QR codes, serial numbers, and traceability across manufacturing industries.

A bölünmüş fiber lazer markalama makinesi is a compact, industrial marking solution that separates the control cabinet from the laser head. This design makes the machine easy to position inside workshops, production lines, and tight spaces. Unlike CO₂ lasers and mechanical tools, a fiber laser marking machine uses a thin, high-energy laser beam to mark, engrave, or deep-engrave materials with precision.

At the center of this system is a fiber laser source, commonly from brands such as Raycus, Max, or JPT. The laser beam travels through optical fiber, is amplified, then reflected and guided by a galvanometer—a high-speed scanning lens system—to move the beam rapidly across the surface. The field lens focuses energy into a precise marking spot, maximizing marking quality while minimizing heat-affected zones.

The split structure gives users freedom. The machine is small, yet powerful enough for industrial marking for metal, plastics, anodized aluminum, and more. Because it uses air cooling, no water chiller is required, reducing maintenance. In industrial environments—sheet metal, hardware, automotive components—this machine delivers permanent marking, part numbers, traceability codes, serial numbers, and intricate designs that do not wear off.

Traditional engraving depends on physical contact, engraving bits, burr removal, and frequent tool replacement. In contrast, fiber laser marking and fiber laser engraving never touch the material. That means no tool wear, no deformation, and no downtime from broken cutters.

Modern manufacturing demands high-precision, durability, and faster marking speed. A fiber laser engraver checks every one of these boxes. It can engrave metal parts in seconds and maintain marking precision at ±0.01mm. Marking fields include production lot codes, logos, QR tracking, product IDs, and barcode packages. For users marking hundreds or thousands of parts, a fiber laser marking machine delivers consistency that mechanical engraving cannot match.

Fiber lasers stand out because they handle a wide range of materials—from stainless steel and anodized aluminum to plastics and non-metallic materials. The beam quality from a JPT laser or split MOPA laser source offers clearer marks, better contrast, and even color marking on certain metals. The fiber laser marker features long service life (100,000+ hours), low power use, and zero consumables—making it the most cost-effective engraving machine for metal and plastics today.

Many buyers assume fiber lasers only work on metal—but the truth is much more exciting.

A split fiber lazer markalama maki̇nesi̇ can mark a wide range of metal and non-metal materials, making it ideal for factories that produce many different parts.

These metals mark with strong contrast and permanent finish—ideal for traceability, deep engraving, and branding.

While fiber lasers don’t cut soft wood or clear acrylic, they excel in marking technical surfaces used in:

Speed is where a fiber laser engraver shines—especially compared to dot peen marking or hand engraving.

A well-tuned bölünmüş fiber lazer markalama makinesi offers:

The marking process has no consumables, no downtime for tool changes, and no risk of scratching delicate parts.

Factories marking thousands of parts per day rely on:

If you are ready to improve marking speed, reduce labor pressure, and upgrade to a future-proof laser solution, Jobon Laser is here to support you.

We proudly serve:

With competitive pricing, fast delivery, OEM customization, and global after-sales support, we help every client maximize capability—no matter the industry or scale.

Tell us what material you mark, what speed you want, and what product you make—

we’ll help you choose the right split fiber lazer markalama maki̇nesi̇ with confidence.

What is the difference between a split fiber laser and an integrated fiber laser?

A split system separates the control cabinet from the marking head.

This gives more flexibility for tight spaces, conveyor lines, large parts, and ergonomic workstations.

Can a split fiber laser marking machine engrave deep into metal?

Yes. Even a 30W split machine can do shallow engrave and light deep marking.

For deeper cuts, 50W or 60W delivers better penetration for steel, brass, and aluminum.

Can it mark plastics or non-metal materials?

Absolutely. Fiber lasers mark many plastic types and coated surfaces.

For delicate plastics or low-heat edges, a MOPA JPT laser performs best.

Does the machine require maintenance or consumables?

No consumables are required for marking.

Basic cleaning of the lens and dust removal is typically enough.

The laser source offers 100,000 hours of average service life.

Can I mark cylinders or round parts?

Yes—with a rotary attachment.

Rotary fixtures synchronize rotation with beam movement to engrave shafts, rings, pipes, and tools.

2026-02

Production deadlines keep getting tighter, yet traditional welding still eats time with sp…

2026-02

Production is tight. Labor is expensive. And traditional welding can leave you with spatte…

Size 24 saat içinde cevap vereceğiz. Acil durum için lütfen WhatsApp/WeChat ekleyin: +86 18053185411,.

*Gizliliğinize saygı duyuyoruz ve tüm bilgiler korunuyor.

Bilgilerinizi yalnızca sorunuza yanıt vermek için kullanacağız ve asla istenmeyen e-postalar veya tanıtım mesajları göndermeyeceğiz.