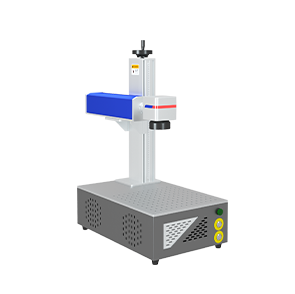

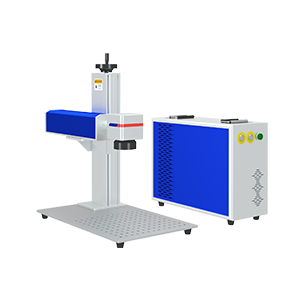

Handheld Fiber Laser Marking Machine

The Jobon Portable Handheld Fiber Laser Marking Machine is expertly designed for precision marking in versatile and hard‑to‑reach environments. With an ultra‑compact, lightweight body (approx. 8.3 kg) and ergonomic handheld structure, this machine delivers portable, on‑site marking without compromise Equipped with a MAX fiber laser source featuring a long service life and reliable continuous‑wave operation, the system supports high‑speed marking up to 12,000 mm/s with excellent beam quality and stable performance. The built‑in 7‑inch touch controller and real‑time positioning aid simplify setup and allow quick adjustment of parameters directly from the interface.