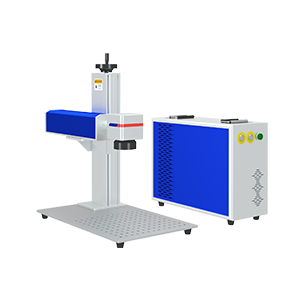

Split Fiber Laser Marking Machine

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

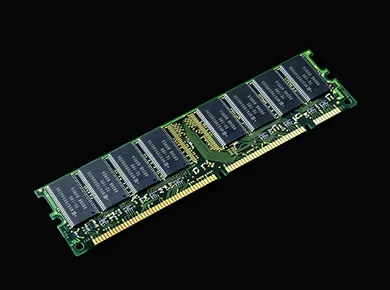

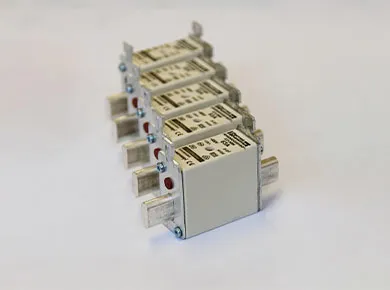

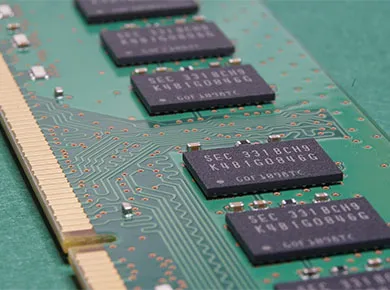

In the fast-paced world of electronics and appliances, where every component must be clearly identified and traceable, laser marking provides unmatched precision and reliability. Whether marking PCB boards, IC chips, charging ports, or appliance casings, laser marking ensures high-contrast, permanent identification without damaging delicate components.

Unlike traditional inkjet or label-based marking methods, laser marking is non-contact, eco-friendly, and highly adaptable to various materials such as plastics, metals, and ceramics. It supports micro-scale marking, QR codes, serial numbers, and brand logos — all with micron-level clarity.

Laser marking provides high-contrast, permanent labels on small, intricate parts without damaging sensitive surfaces. It ensures clear identification of serial numbers, QR codes, and circuit diagrams on components like PCBs, capacitors, connectors, and housings—essential for traceability and quality control.

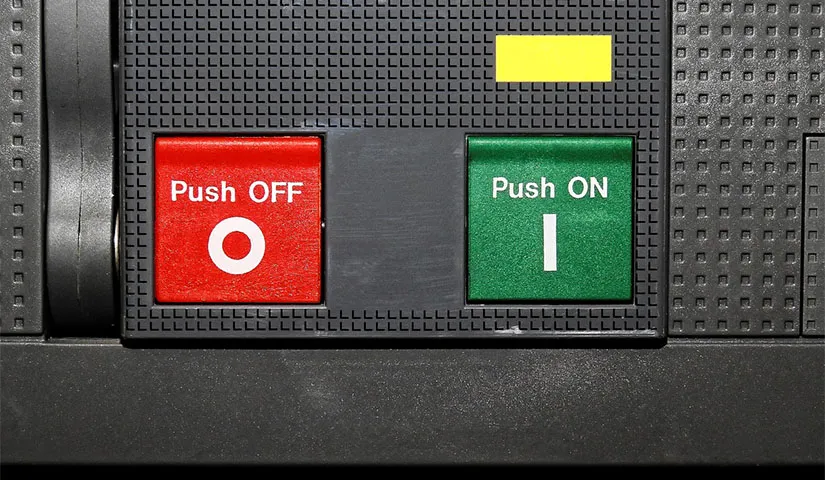

A laser marking machine operates by directing a high-energy laser beam onto the surface of a material, causing localized heating, vaporization, or a photochemical reaction that leaves a permanent mark. The laser beam is precisely focused and controlled to trace specific patterns, such as text, serial numbers, logos, or barcodes, without physically touching the workpiece.

Laser marking is compatible with a wide range of materials, including metals, plastics, ceramics, and glass. It offers key advantages such as high speed, high precision, zero consumables, non-contact processing, and seamless integration into automated production lines.

Widely adopted across industries, laser marking is especially critical in fields like electronics, automotive, medical devices, and aerospace. It enhances traceability, ensures anti-counterfeiting, supports quality control, and boosts brand recognition—all while maintaining durability and aesthetic clarity.

Widely adopted across industries, laser marking is especially critical in fields like electronics, automotive, medical devices, and aerospace. It enhances traceability, ensures anti-counterfeiting, supports quality control, and boosts brand recognition—all while maintaining durability and aesthetic clarity.

| Feature | Laser Marking | Traditional Marking |

| Marking Method | Non-contact laser beam focused on the surface | Contact-based: dot peen, inkjet, chemical etching |

| Precision | Ultra-high (±0.01mm), ideal for fine detail | Lower precision, prone to blurring |

| Material Compatibility | Metal, plastic, glass, leather, ceramic, etc. | Mainly metal; limited on plastics or glass |

| Speed | High-speed scanning with fast turnaround | Slower, depends on tool type |

| Marking Durability | Permanent, heat & corrosion resistant | May fade, wear off, or peel |

| Environmental Impact | No consumables, no emissions | Involves ink, chemicals, or noise |

| Maintenance Cost | Almost zero; long lifespan up to 100,000 hours | Frequent consumables or part replacements |

| Operator Safety | Enclosed lasers with safety protocols | Risk of noise, splashing, fumes, or contact injury |

| Automation Ready | Easy to integrate with robotic arms & conveyors | Hard to automate, usually stand-alone tools |

| Design Flexibility | Real-time software changes (text, QR, logo) | Requires physical setup changes or new ink |

| Typical Industries | Automotive, electronics, packaging, tools, medical | Traditional metalworking, low-cost marking |

| Machine Types | Fiber, UV, CO₂, Handheld, Flying Laser | Dot peen machines, chemical etching, inkjet |

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

It is widely used in food and beverage, electronic components, pharmaceutical packaging and other high-volume production scenarios, significantly improve the production line efficiency and automation level.

Our desktop fiber laser marking machine offers high-speed, high-precision marking with zero consumables and no maintenance. It features stable beam quality, long service life, and wide compatibility with metals, plastics, and coated materials—ideal for industrial engraving needs

The Jobon Portable Handheld Fiber Laser Marking Machine is expertly designed for precision marking in versatile and hard‑to‑reach environments. With an ultra‑compact, lightweight body (approx. 8.3 kg) and ergonomic handheld structure, this machine delivers portable, on‑site marking without compromise Equipped with a MAX fiber laser source featuring a long service life and reliable continuous‑wave operation, the system supports high‑speed marking up to 12,000 mm/s with excellent beam quality and stable performance. The built‑in 7‑inch touch controller and real‑time positioning aid simplify setup and allow quick adjustment of parameters directly from the interface.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.