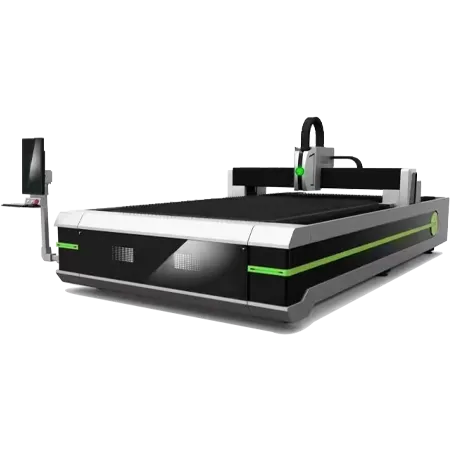

High-Speed Production with Clean Finishes

Equipped with imported servo motors and precision guide rails, the machine ensures smooth cuts, minimal burrs, and high repeatability. Perfect for mass production of components such as boom arms, outriggers, and protective structures.

Automatic Loading & Smart Nesting System

The integrated loading/unloading system and intelligent nesting software reduce material waste and manual handling—accelerating workflow and lowering labor costs in large-volume production environments.

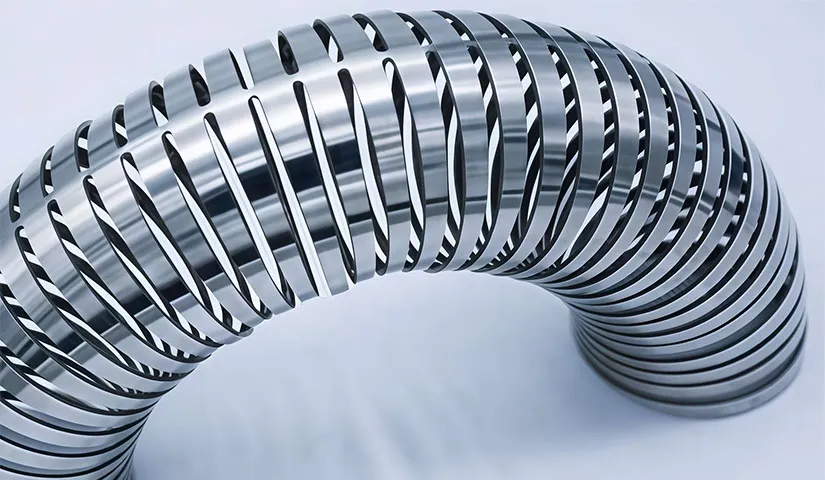

Stability and Longevity in Harsh Work Environments

Designed for 24/7 industrial use, the 3D laser cutter adopts reinforced mechanical structures and long-life laser sources, ensuring durability even under high workloads typical of construction equipment factories.