CW laser cleaning machine - Model A

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

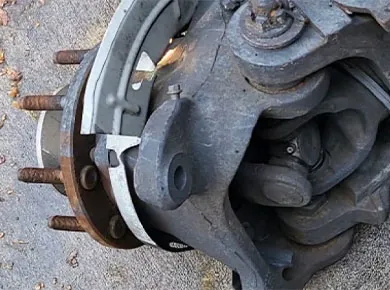

Rust on metal is the result of electrochemical corrosion, most commonly occurring on iron or steel. When iron reacts with oxygen and moisture, it forms various iron oxides that collectively appear as rust.

Rust typically has a layered, porous structure. The outer layer is loose α-Fe₂O₃ (reddish brown), the middle layer is a mixture of γ-FeOOH (yellowish brown) and Fe₃O₄ (black), and the inner layer is the dense Fe₃O₄. This porous structure absorbs moisture and oxygen, allowing corrosion to continue deeper into the metal. The rust layer expands to several times the volume of the original iron, causing surface cracking and accelerated deterioration.

Pulsed laser cleaning uses high-energy laser pulses to irradiate the metal surface, instantly vaporizing or ablating the oxide layer without damaging the underlying substrate. Unlike traditional mechanical or chemical cleaning methods, laser cleaning is non-contact, requires no consumables, and produces no secondary pollution.

The system delivers precise and selective cleaning even in small areas or complex surfaces. Thanks to its low thermal impact, it preserves the physical properties of the base material, making it ideal for pre-welding, plating, or bonding processes where oxide layers must be thoroughly removed to ensure strong adhesion and optimal conductivity.

Hand-held precision cleaning for selective cleaning at precise locations and sizes. Compared with the traditional mechanical, chemical cleaning of rough processing, high cost, environmental pollution, pulsed laser cleaning has no media, no secondary pollution, simple operation, non-contact cleaning and other advantages. Compared with the continuous laser cleaning, pulse cleaning can be done without high temperature, without damaging the characteristics of the workpiece substrate. Small size, easy to carry, easy to operate, and has a stable cleaning system.

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution. The washing head is lightweight and the powerful water cooling system ensures that the equipment runs uninterrupted for 24 hours. It can achieve precise positioning, fast cleaning speed and high efficiency. The focal length position can be adjusted according to different scenes, which is convenient and fast.

Rust removal is critical in metal maintenance, repair, and surface treatment. While traditional rust removal methods remain widely used, laser cleaning technology is quickly emerging as a safer, more efficient, and eco-friendly alternative. Below is a comparison of laser rust removal and conventional methods, categorized by their working principles.

| Feature | Laser Rust Removal | Traditional Methods |

| Contact Type | Non-contact, no tool wear | Physical or chemical contact |

| Base Material Damage | Minimal, especially with pulsed lasers | High risk of surface damage or pitting |

| Precision | High (suitable for delicate parts) | Low (broad impact area) |

| Environmental Impact | No chemicals or waste | Generates hazardous waste or dust |

| Operation Cost | Higher initial investment, low maintenance | Low initial cost, high recurring costs |

| Automation Integration | Easy to integrate into CNC/robot systems | Difficult to automate |

| Noise & Safety | Low noise, safer working environment | Loud, requires protective measures |

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld after welding, coating, removal of rust on metal, rapid removal of paint, etc.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.