CW laser cleaning machine - Model A

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution. The washing head is lightweight and the powerful water coolingl system ensures that the equipment runs uninterrupted for 24 hours. It can achieve precise positioning, fast cleaning speed and high efficiency. The focal length position can be adjusted according to different scenes, which is convenient and fast.

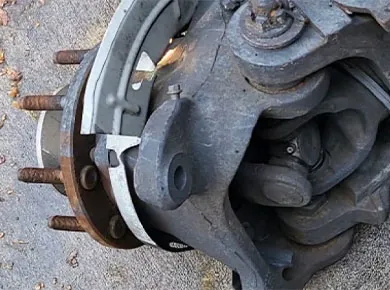

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld after welding, coating, removal of rust on metal, rapid removal of paint, etc.

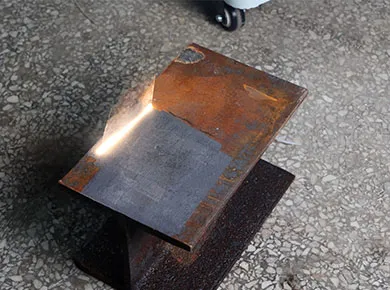

CW laser rust removal works by directing a continuous, high‑energy laser beam onto the corroded metal surface, rapidly heating the rust layer until it expands, cracks, and separates from the underlying substrate. As the temperature rises, the oxide layer undergoes photothermal decomposition, causing micro‑explosions that break the corrosion into fine particles. These loosened residues are then vaporized into smoke or blown away through airflow or vacuum extraction.

Thanks to the strong penetration capability of continuous‑wave output, CW lasers are especially effective on thick and stubborn rust, allowing the beam to reach deeper corrosion layers than pulsed models. When operated with proper settings, the process removes rust efficiently while maintaining the integrity of the base metal, achieving fast cleaning speeds and consistent surface restoration suitable for heavy‑duty industrial applications.

Our system is designed to achieve the industry standard of “only clean the contaminant, not the base.” Whether you’re working with stainless steel, painted surfaces, stone reliefs, or fragile heritage objects, the laser cleaning process leaves the original surface unharmed.

| Aspect | Laser Rust Removal | Traditional Methods (e.g., Sandblasting, Chemical, Mechanical) |

|---|---|---|

| Cleaning Method | Non-contact, uses focused laser beam to vaporize oxide/rust | Physical contact or chemical reaction-based methods |

| Precision | High precision; selectively removes rust with controlled depth | Low precision; difficult to control removal area |

| Effect on Substrate | No damage to the base material when operated correctly | May scratch, erode, or corrode the underlying metal |

| Environmental Impact | Eco-friendly, no chemicals, low waste, minimal pollution | Can produce toxic fumes, chemical waste, and significant dust |

| Operator Safety | Safe with proper extraction and shielding; minimal exposure | Risk of inhaling dust or chemical vapors; heavy protective gear often needed |

| Material Compatibility | Suitable for metals, alloys, cultural relics, and sensitive components | Mostly suitable for coarse or robust materials |

| Consumables & Maintenance | No consumables needed; long equipment life | Frequent replacement of abrasives, chemicals, or brushes |

| Automation Potential | Easily integrated with robotic arms, CNC systems, or automated production lines | Mostly manual operation, low automation |

| Post-Treatment Needs | Surface is ready for painting, welding, or inspection directly after cleaning | Often requires secondary cleaning or surface prep |

| Use Cases | Ideal for industrial components, molds, pipelines, automotive parts, precision tools | Common for rust-heavy surfaces, large structures, pipelines |

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld after welding, coating, removal of rust on metal, rapid removal of paint, etc.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.