CW laser cleaning machine - Model A

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

Preserving cultural relics and historical monuments requires a cleaning method that is gentle, precise, and safe. Traditional techniques like sandblasting or chemical soaking risk damaging delicate stone carvings, inscriptions, or sculpture surfaces.

Laser cleaning technology provides a groundbreaking solution—removing dust, biological growth, oxide layers, and pollution crusts without contact or abrasion. It’s ideal for stone tablets, sculptures, tombstones, architectural facades, and heritage artworks in museums or open-air sites.

1.Dust may contain acidic or alkaline substances. When moisture is absorbed, it can corrode metal, discolor paper, or degrade pigments.

2.Dust covers artifact surfaces and obscures details. Cleaning may cause scratches, especially on fragile materials like lacquerware and paintings.

3. Organic matter in dust provides a breeding ground for mold and insects, posing threats to textiles and calligraphy or paintings.

4.Dust accumulations retain moisture and heat, altering temperature and humidity around artifacts, which may lead to localized mildew or oxidation.

Laser cleaning machines provide a highly efficient, eco-friendly, and non-contact solution for removing surface contaminants such as paint, rust, oil, oxide layers, carbon deposits, and dust. Utilizing high-energy pulsed fiber lasers, the system vaporizes and separates unwanted materials without damaging the underlying substrate—making it ideal for industrial, historical, and commercial cleaning applications.

Zero Abrasion, No Chemicals

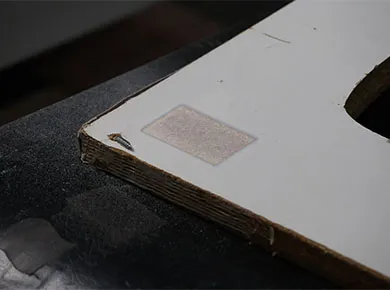

Laser cleaning does not rely on abrasive materials, water, or chemical solvents. This dry process avoids corrosion, eliminates secondary pollution, and maintains the integrity of delicate surfaces like stone carvings, metal molds, and painted components.

High-Precision Laser Beam Control

With adjustable power, frequency, and scanning width, our intelligent system targets only the contaminants—ensuring accurate removal even in complex geometries, fine engravings, or layered coatings.

Eco-Friendly & Low Maintenance

Unlike traditional sandblasting or chemical stripping, laser cleaning reduces hazardous waste, requires minimal consumables, and dramatically lowers operator exposure to harmful residues.

Touchscreen Interface: User-friendly digital control with memory presets for various materials and thicknesses.

Pulsed or Continuous Wave Mode: Adapt to both delicate cleaning and deep-layer stripping.

Auto-Focus & Path Planning: Optional robotic arm integration for automated production lines.

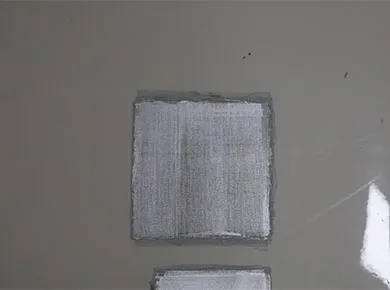

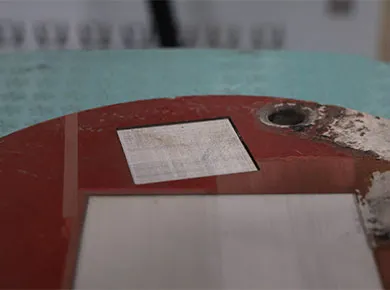

Our system is designed to achieve the industry standard of “only clean the contaminant, not the base.” Whether you’re working with stainless steel, painted surfaces, stone reliefs, or fragile heritage objects, the laser cleaning process leaves the original surface unharmed.

| Feature | Jobon Laser Cleaning | Traditional Cleaning |

|---|---|---|

| Contact Type | Non-contact, no tool wear | Abrasive, physical contact |

| Substrate Protection | No damage to fine carvings or inscriptions | High risk of micro-cracks |

| Precision Cleaning | Adjustable laser pulse for targeted spots | Difficult on curved/porous surfaces |

| Environmental Impact | No chemicals, no waste | May leave residues or damage soil |

| Portability | Compact & mobile for field work | Bulky tools or equipment needed |

| Cleaning Control | Programmable intensity and depth | Manual skill-dependent |

The laser cleaning machine adopts non-contact cleaning, which is energy-saving and environmentally friendly, and has no secondary pollution.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld after welding, coating, removal of rust on metal, rapid removal of paint, etc.

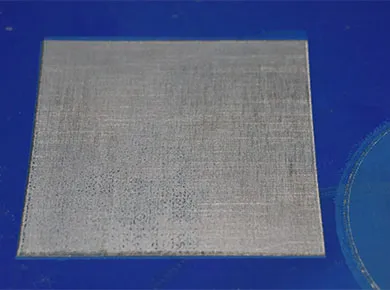

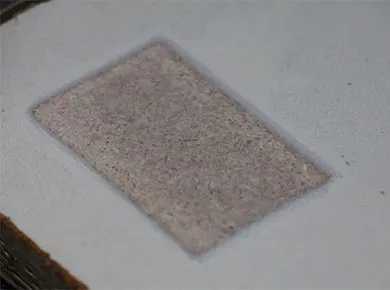

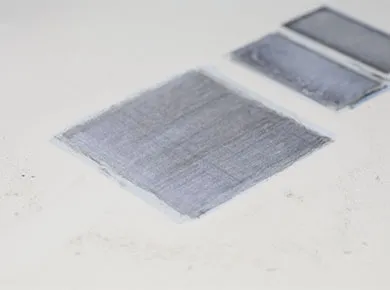

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

This is continuous laser cleaning machine with a power of 1000w ,1500w, 2000w, 3000w, 6000W. It’s mainly used for rust removal, paint removal, glue removal, coating removal, and plating removal with high efficiency. It’s mainly used for rust removal, paint removal, and glue removal. It’s suitable for cleaning the rust layer and thick paint layer, as well as surface roughening, welding seam cleaning and other process links, with extremely high efficiency.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

It is suitable for ship, boiler, steel surface, product surface treatment before welding, treatment of oxide layer in and around the weld seam after welding, coating, removal of rust on metal, rapid removal of paint, etc.

Live demonstration of our machines? Or a custom quote?

Feel free to contact our experts!

We will help you choose the suitable machine and share you the solution;you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine , for product welding or repair or other application

We will send operation video and manual for the machine. Our engineer will do training online If needed. we can send our engineer to your site for training or you can send the operator to our factory for training.

We provide two years machine warranty. During the two-year warranty,in case any problem for the machine,we will provide the parts free of charge(except for artificial damage). After the warranty. we still provide whole lifetime service. So any doubts,just let us know, we will give you solutions.

We accept payment terms including: T/T, VISA, Western Union Online Bank payment.

Sea transportation is the normal way. If there are special requirements, the two sides need to confirm the final.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86 18053185411,.

*We respect your confidentiality and all information are protected.

We will only use your information to respond to your inquiry and will never send unsolicited emails or promotional messages.