| Cleaning Principle |

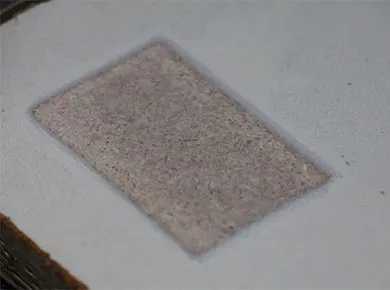

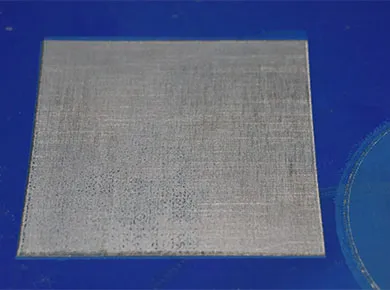

High-energy laser vaporizes contaminants |

Chemical dissolution reaction |

Cryogenic impact removal |

Physical abrasive impact on surface |

| Substrate Damage |

No damage, non-contact cleaning |

Possible corrosion or erosion |

Minimal impact |

Likely to cause surface wear |

| الأثر البيئي |

Eco-friendly, no chemicals or secondary waste |

Chemical residue may pollute environment |

No residue, dry and clean |

Dust generation, high noise & pollution |

| الدقة |

Extremely high, supports micron-level control |

Difficult to control with accuracy |

Medium precision |

Low precision, large-area treatment |

| المواد الاستهلاكية |

No consumables needed |

Chemical agents, PPE required |

Dry ice pellets |

Sand, shot media, and disposal bags |

| Maintenance Needs |

Low, mainly optics cleaning |

High, chemical handling and storage |

Medium, dry ice handling |

High, frequent media replacement |

| Cost Structure |

High initial investment, low long-term cost |

Low upfront, high ongoing chemical cost |

Medium initial and recurring cost |

Low equipment cost, high media consumption |

| Automation Potential |

Easily integrated with robotic arms |

Hard to automate complex chemical handling |

Semi-automated possible |

Difficult to automate due to media flow |

| سلامة المشغل |

High safety with proper shielding |

Risk of chemical burns and toxic exposure |

Cold burn risk, needs protection |

Dust inhalation and injury risks |

| Best Use Cases |

Precision cleaning of rust, paint, oil, oxide |

Heavy oil or grease cleaning |

Food-grade and sensitive component cleaning |

Paint stripping, rust removal on large parts |